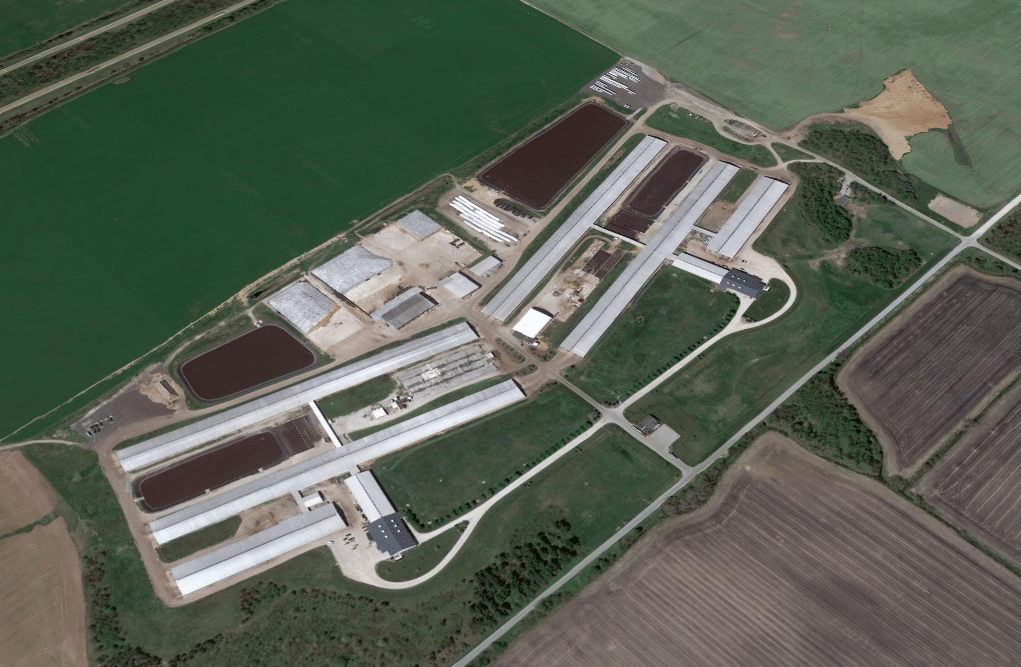

Dairy Renewable Natural Gas (RNG) in Fair Oaks, Indiana

Jasper County Cow Power

Overview

600 tons of daily cow manure is collected from three farms and transported to anaerobic digesters for biogas capture. Through DMT’s fully integrated system, hydrogen sulfide (H₂S) and carbon dioxide (CO₂) is removed from the biogas stream to create renewable natural gas (RNG), which is injected into the natural gas pipeline and subsequently sold as transportation fuel.

- < 75 ppm for H₂S removal with the Sulfurex®BR

- < .85 caustic consumption average (kg NaOH/kg S)

- < 2% of CO₂ in the product gas

Project Details

Year: 2018

Location: Fair Oaks, IN / USA

Product: Sulfurex®BR & Carborex®MS

Biogas Inlet: 1500 SCFM

H₂S Concentration: 4000 to < 75 ppm

Biogas Source: Dairy Manure

Application: Pipeline Injection

About the Dairy RNG Project

The dairy renewable natural gas (RNG) facility in Fair Oaks, Indiana represents a huge milestone for not only DMT but also for the U.S. In fact, this dairy RNG project is the first system in the U.S. to use DMT’s fully integrated system. This entails the Sulfurex® BR for H₂S removal and the Carborex® MS for CO₂ removal.

This RNG facility processes 600 tons of daily manure, as a result of 16,000 milking cows collected by three farms. Once transported to a centralized site, the biogas becomes RNG using DMT’s technology for conditioning and upgrading. The compressed RNG is then injected into the NIPSCO natural gas pipeline and subsequently sold as transportation fuel.

“We are proud to be recognized for our contributions in improving air quality, sustainability and farm profitability. Jasper is now the country’s largest dairy RNG project, but there is still tremendous opportunity out there to convert dairy waste into 100 percent renewable transportation fuel. We look forward to working on more innovative projects with DMT.”

Grant Zimmerman, CEO, AMP Americas

Project Results

At 1,500 SCFM, this dairy renewable natural gas project equates to the annual CO₂ emissions generated from 2.7 million gallons of gasoline. The Sulfurex®BR handles the bulk removal of H₂S while the Carborex®MS extracts the CO₂ from the CH4 stream. The full integration of both system allows operators to use the same interface throughout the entire process. Additionally, the client only has to deal with one supplier.

In operation, the biogas inlet has H₂S concentrations as high as 4,500 ppm. However, this dairy RNG plant was initially designed to handle up to 3,000 ppm. Through modifications, the Sulfurex®BR has proven robust in its design and is able to remove H₂S to less than 75 ppm.

“The H₂S system has been meeting all of my requirements with no issues. It’s removing the H₂S with ease and doing a great job. Doesn’t matter if I’m bringing in nameplate or just above nameplate. It’s easily capable of processing out to under 75 ppm of H₂S.”

Jason Bond, Director of RNG Service Delivery, AMP Americas

Project Recognition

Following its completion in 2018, this RNG facility was the largest dairy-biogas-to-transportation-fuel project in the nation. Additionally, the dairy RNG facility won the American Biogas Council’s “Innovation of the Year” award for effectively combining biogas upgrading technologies.

“Our awards this year recognize projects that are great examples for future projects— a great new tool for finding nutrient recovery technologies and a champion for the biogas industry. We are so proud to be awarding these shining stars of the industry.”

Patrick Serfass, Executive Director, American Biogas Council

Large in scope, this award-winning dairy RNG project is a model for sustainable dairy farming across North America. It demonstrates the many benefits of converting biogas from dairy manure into RNG:

- Repurposing waste,

- Protecting the health of the land through nutrient management, and

- Generating substantial financial returns for all farm partners.

This RNG facility uses the Sulfurex®BR & Carborex®MS.

For key biogas contaminants, DMT offers one or a combination of technologies. The technology selection is based on an analysis of your biogas composition, inlet gas flow, pollution load and RNG application. Based on your CAPEX, OPEX and/or TCO needs, we provide our customers with an innovative, economical solution.