Sulfurex®BR

Biological Regeneration & Elemental Sulfur

Choose the Sulfurex®BR.

The Sulfurex®BR combines the flexibility and reliability of caustic scrubbing technology with the low operational cost of a biological system. Continuous regeneration of the caustic solution results in more than 99% of H₂S removal with minimal chemical consumption.

- No oxygen addition to gas.

- Sulfur fertilizer by-product.

- Suitable for high H₂S concentrations.

H₂S Removal Using Both Biological and Chemical Technology

Using both biological and chemical technology for H₂S removal offers significant ROI savings when removing high H₂S concentrations from the biogas stream. At high concentrations, biological systems can clog while frequent disposal of spent adsorption media or high-caustic consumption will result in costly operational expenses. How do you integrate biological and chemical technology? This is where DMT can help.

Convert hydrogen sulfide into elemental sulfur.

The Sulfurex® BR removes hydrogen sulfide (H2S) from the biogas and produces elemental sulfur as a by-product. Elemental sulfur is a sulfur sludge by-product that can be repurposed as high-quality fertilizer.

How does the Sulfurex®BR work for H2S removal?

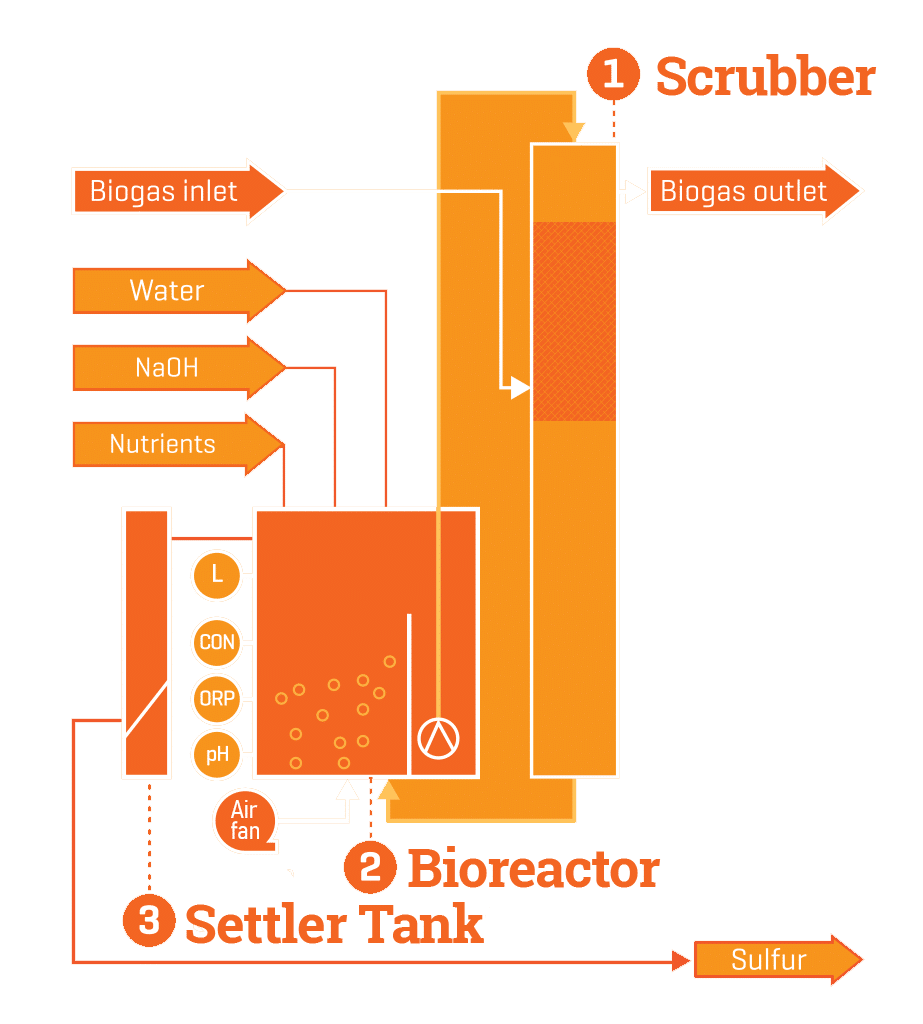

DMT’s biological and chemical technology, the Sulfurex® BR, consists of a

- Scrubber,

- Bioreactor, and

- Settler Tank.

H2S is absorbed by the caustic solution and converted into sodium hydrosulfide (NaHS). The saturated caustic flows to the bioreactor, where low concentrations of dissolved oxygen activate the bacteria to convert NaHS into elemental sulfur.

The addition of oxygen to the bioreactor allows optimal removal of elemental sulfur, while also guaranteeing the biogas retains its caloric value and is not degraded with nitrogen or oxygen.

During this biological process, the caustic solution is continuously regenerated and reused in the chemical scrubber.

Scrubber

A chemical scrubber, or adsorber, washes the raw biogas with a caustic solution. As a result, the H2S will dissolve in the process liquid. The packing media positioned inside provides optimal contact between the gas and the caustic solution, supported by a grid. The spent caustic then flows to the bioreactor to recover the caustic solution. The main process of this desulfurization technique is scrubbing the raw gas with a caustic solution to desulfurize the raw gas.

Bioreactor

The biological recovery of the caustic occurs in the bioreactor. The hydrogen bisulfide (HS–) is oxidized by the bacteria into elemental sulfur. In this step, the process liquid is regenerated and recirculated back into the scrubber to wash the raw biogas.

The bacteria used is highly resilient to various process conditions and grows very quickly. Inside the bioreactor, water, nutrients and caustic are automatically distributed for optimal bacteria conditions and cellular growth. Its air distribution system provides oxygen transfer and mixing of the process liquid, preventing anaerobic pockets in the bioreactor.

Settler Tank

Inside the settler tank, the elemental sulfur is separated from the process liquid. The suspended solids and sulfur need to be removed from the system to avoid accumulation. Sulfur particles settle at the bottom and form a sediment. The top layer with low suspended solids overflows to the bioreactor.

The sediment is then discharged, creating elemental sulfur.