Sulfurex®BF

Biotrickling Filter

Choose the Sulfurex®BF.

Achieve high H₂S removal efficiency with no chemical consumption using our Biotrickling Filter (BF) technology. This simple solution offers a compact but robust construction, and complete monitoring of process conditions such as pH, temperature, nutrients and the oxygen level.

- Low OPEX.

- Low CAPEX.

- No chemicals.

H₂S Removal Using A Biotrickling Filter

Under proper operation, a biological system for H₂S removal is highly efficient and environmentally friendly. Its low operating cost attributes to the use of microbial oxidation at ambient conditions instead of thermal or chemical oxidation conditions. The most widely utilized bioreactors for air pollution control are biofilters and biotrickling filters. Advantages of biotrickling filters include reduced OPEX due to no chemical consumption.

How does the Sulfurex®BF work?

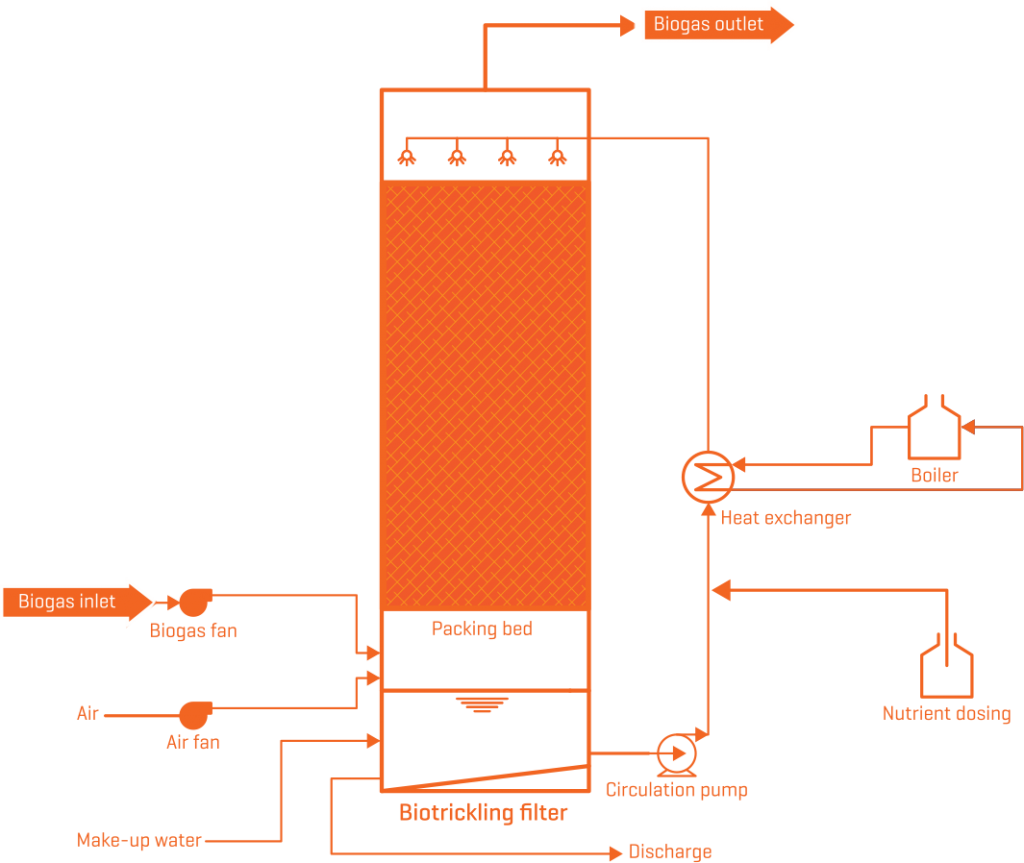

A biotrickling filter functions by passing the contaminated air stream through a moist bed of permeable material, on which liquid biofilms are formed. A biotrickling filter is, in fact, a three-phase biocatalytic oxidizer and is essentially made from a support carrier on which microorganisms are able to grow when optimal conditions are provided. Thus contaminants are induced to diffuse from the gaseous phase through the wet biofilm and are consequently catabolized aerobically.

Biological Desulfurization

In the bioreactor, bacteria convert H2S into elemental sulfur and/or sulfuric acid. Oxygen is added to the gas by an automatic control system, which adjusts the airflow based on the biogas flow and outlet oxygen concentration. Monitoring and control of process conditions like pH, temperature, nutrients and oxygen level ensure maximal H2S removal efficiency.

Inside the Sulfurex®BF, nutrients and water are automatically refreshed, sprayed on top of the packing bed and circulated over the bioreactor. The water is heated through a heat exchanger to create the optimal temperature for the bacteria. The produced sulfuric acid and excess biomass are removed through the draining process. Additionally, the system is easy to maintain because it does not include extra pumps and piping necessary for water recirculation.

Packing Material Selection

In both biofilters and biotrickling filters, the selection of packing materials is an important factor in establishing a high removal efficiency. Additionally, the different types of forces involved in the microbial attachment to different types of packing material, such as electrostatic/hydrophobic interactions or covalent/partial covalent bond formation, can affect bioreactor performance over the long-term. DMT selects the best packing media, pall rings, due to their high surface area, hydrophobic properties, and ability to minimize pressure loss due to sulfur or biomass accumulation.