🏆 This project is nominated for the AD and Biogas Industries Awards in the category ‘Best Biogas Plant Above 1MWe Equivalent’

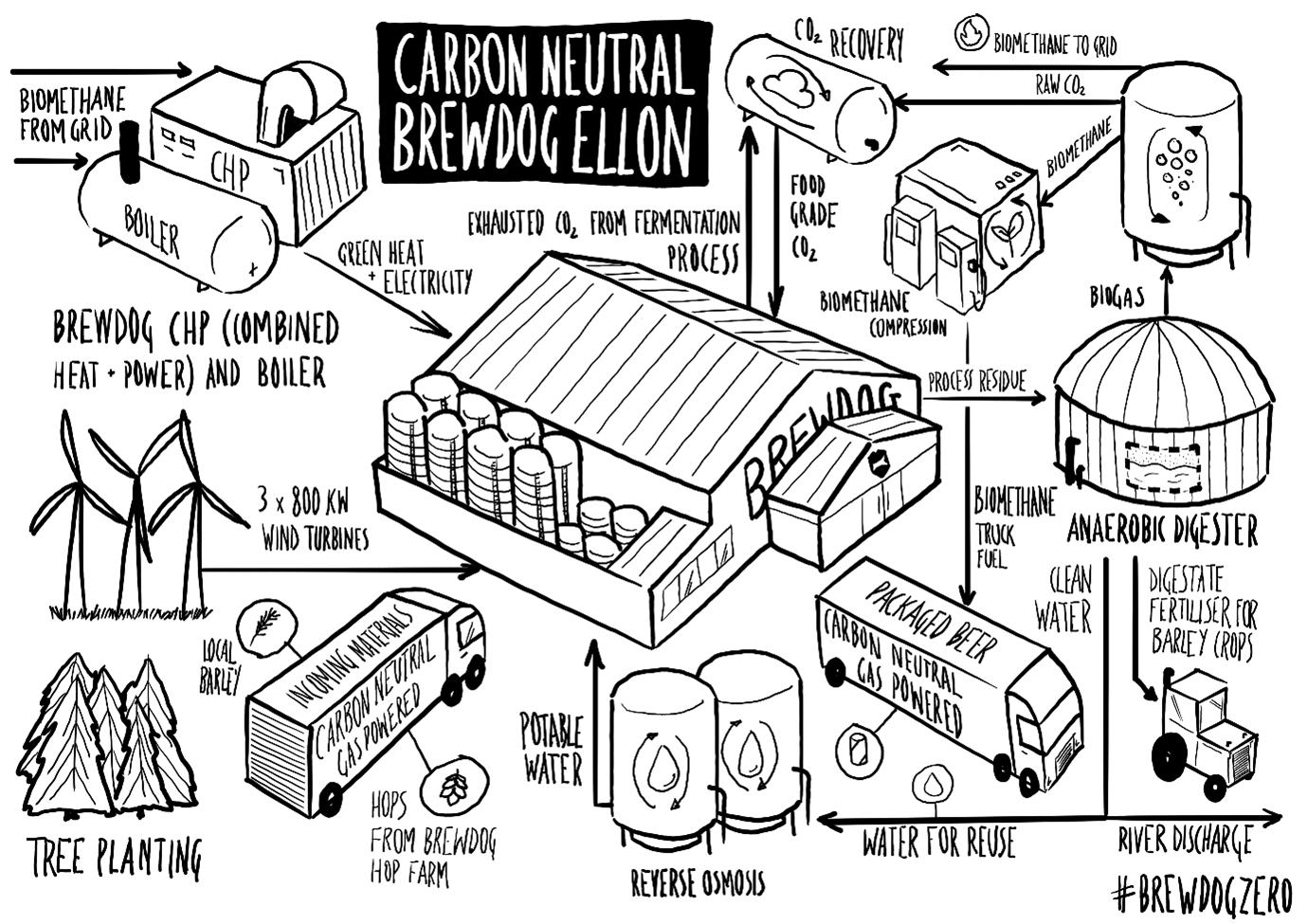

The Brewdog Brewery makes biogas from leftover grain and that helps fight climate change by producing renewable energy Through DMT’s three-stage membrane separation technology, biogas from two anaerobic digesters is processed and upgraded to a purified Biomethane stream which is then injected into SGN’s pipeline to provide thermal energy for homes and businesses in the local town of Ellon.’ Biogas upgrading at BrewDog’s HQ bio-plant At many breweries, the rinse water used in the brewing process is purified and reused. The wastewater treatment plant at the BrewDog HQ bio-plant will reduce the water usage of the brewery by 50%. A waste stream containing sludge is released during this purification process. This sludge is transferred to a digester and here a digestion process takes place in which biogas is produced. The biogas at the BrewDog brewery has a typical biogas composition, 55% methane, 44% carbon dioxide and some gasses with impurities such as H2S. Biogas upgrading means separating the gas into main streams; one stream will be almost 100% pure carbon dioxide and the other stream (bio) methane will be above 97%. The CO2 can be reused in the brewing process thereby lowering CO2 emissions and closing the circle by using the CO2 as a product that otherwise would have gone to waste.

Targeting zero net emissions

DMT will supply the biogas upgrading technology with a capacity to clean 600Nm3 per hour. The biogas upgrading plant is a key part of BrewDog’s zero emissions goals and is expected to inject the first gas to SGN’s gas grid in February 2022. Since DMT’s first UK project in 2012 DMT has installed and maintained many projects in the United Kingdom.

DMT’s team in the UK will take care of the daily management of the scope, working closely together with SGN and our partner Heat & Power Services to ensure timely delivery of a successful project. The RHI deadline is 31of March 2022 therefore the next 12 months are critical for biogas upgrading projects. As DMT has the experience and proven to be successful under similar deadlines, we are confident of delivering another project on time.

Creating a sustainable future

The project with BrewDog is a great example and shows how innovative technologies can be used to reduce carbon emissions and contribute to a cleaner environment, creating a sustainable future. DMT’s has a wealth of experience helping companies achieve their sustainability goals. Our mission is to reduce the environmental burden and is very similar to BrewDogs. Since DMT was founded in 1987 it has developed technologies to solve environmental issues.

More information about the AD & Biogas Awards can be found here: https://adbioresources.org/events/awards/