Big Run Landfill Renewable Natural Gas Project

Kentucky’s Largest RNG Project

Overview

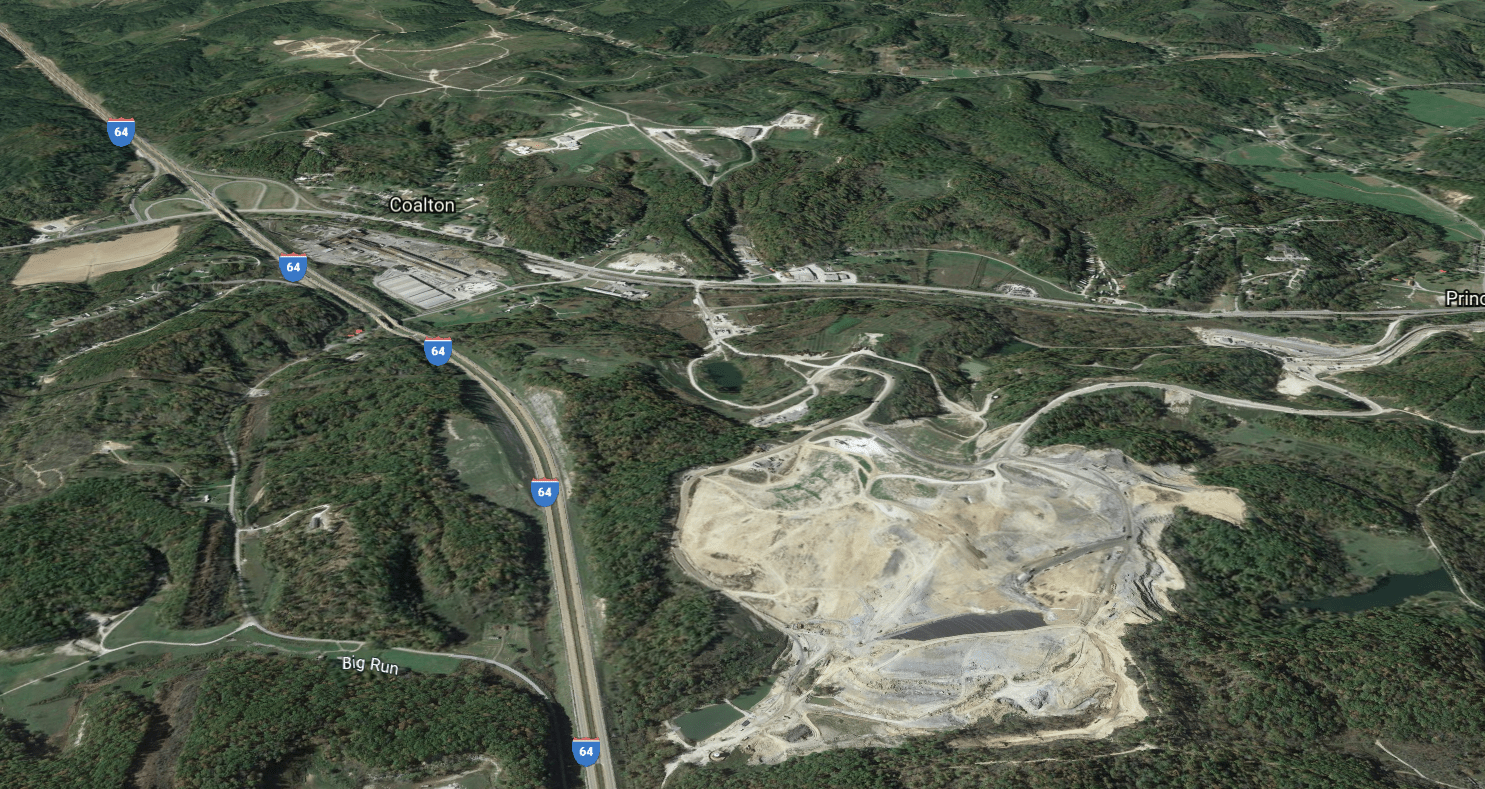

In 2019, Big Run Landfill became the largest operating renewable natural gas (RNG) facility in the state of Kentucky. Large in scope, this projects upgrades 4,000 SCFM of previously flared landfill gas (LFG) into RNG, which is injected into the Columbia Gulf Transmission Pipeline and sold into the transportation fuels market. Satisfying stakeholders from residents to off-takers, this project demonstrates how landfill RNG projects offer a circular economy.

- 40% of the RNG is purchased by L’Oréal

- 97% CH₄ recovery from two-stage membranes

- 7.3 million gallons of gasoline displaced

Project Details

Year: 2019

Location: Ashland, KY

Product: Sulfurex®BR & Carborex®MS

Biogas Inlet: 4000 SCFM

H₂S concentration: 2000 to < 100 ppm

Biogas Source: Landfill

Application: Pipeline Injection

About Kentucky’s Largest RNG Project

Since March 2019, Big Run Landfill remains the largest renewable natural gas (RNG) project in the state of Kentucky. Large in scope, this facility provided an opportunity for DMT and all stakeholders, including the developer, engineering firm and EPC, to break ground and successfully convert 4,000 SCFM of previously flared landfill gas (LFG) into a purified RNG stream of 97 percent. Additionally, this pipeline-quality RNG goes into the Columbia Gulf Transmission Pipeline, a 3,340 mile-pipeline that provides energy to four states. The RNG is then sold into the transportation fuels market.

“A project of this scale was definitely a challenge and the Venture team was pleased to partner with DMT Clear Gas Solutions for a successful project.”

Dave Moniot, President & CEO, Venture Engineering

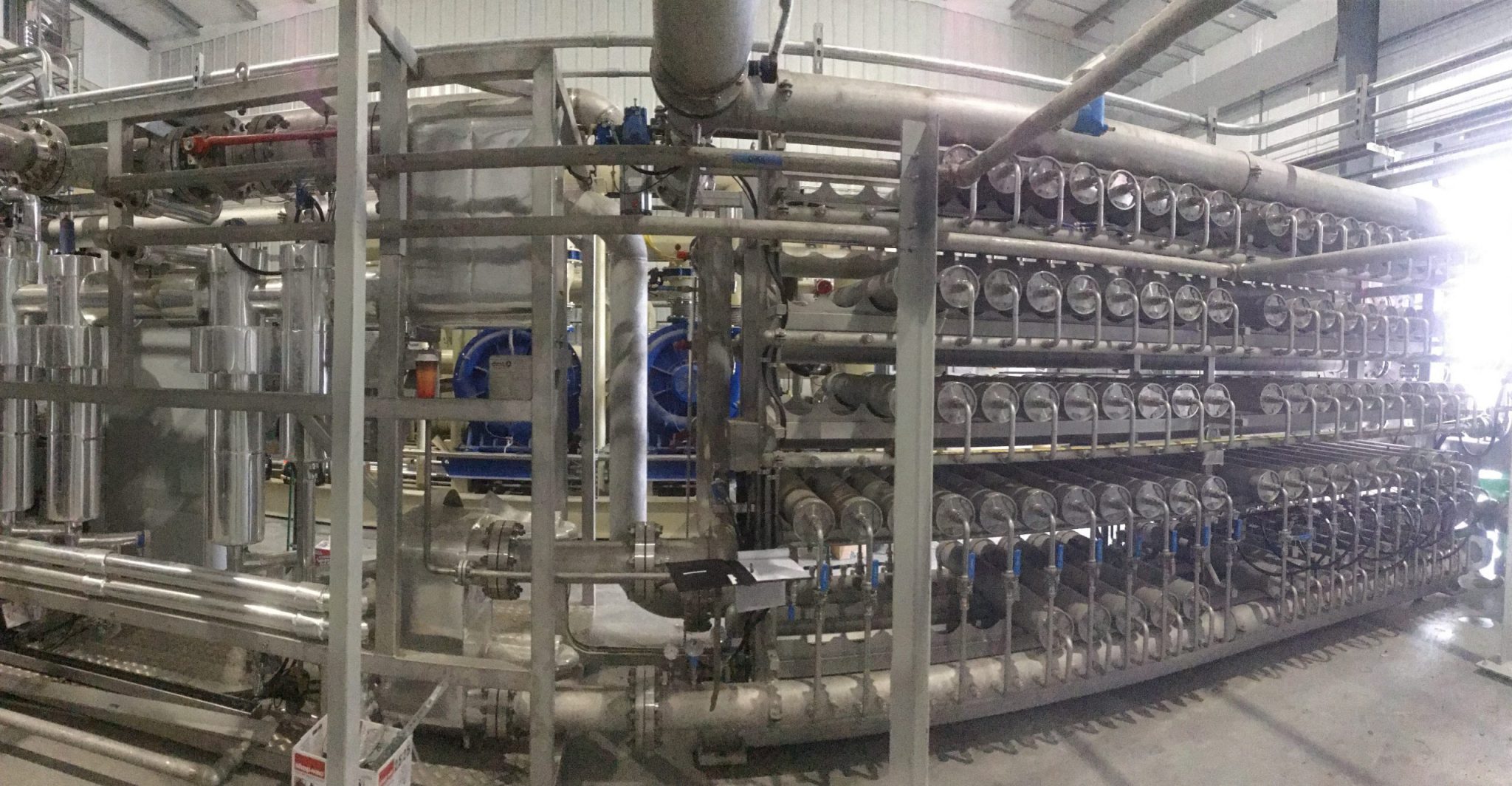

DMT provided a fully integrated system using:

- the Sulfurex®BR for hydrogen sulfide (H2S) removal and

- the two-stage Carborex®MS for carbon dioxide (CO2) removal.

In partnership with Ultra Capital, who owns Big Run Power Producers, and Venture Engineering & Construction, this RNG plant also features siloxane and volatile organic compound (VOC) treatment as well as a nitrogen rejection unit.

Project Results

This landfill RNG project is a huge accomplishment. For not only DMT and the stakeholders involved, but also for the state of Kentucky itself. In 2015, Boyd County residents complained about the landfill odor. The case resulted in an agreed order to place stricter emission restrictions on the landfill as well as capture and convert the previously flared biogas. This RNG project satisfies this agreed order.

Additionally, L’Oréal signed a 15-year agreement to purchase 40 percent of the total RNG produced from the Big Run Landfill. This critical move helped the global giant reach carbon neutrality for 51 of its manufacturing and distribution facilities by 2019. Additionally, this long-term purchase commitment was a key component that led to the financing of this RNG project.

Landfills make up 20% of human-related methane emissions in both the U.S. and Canada. Given the number of landfills in the U.S. that have the potential to convert LFG into RNG, this RNG project serves as a model across the nation that these projects are both environmentally and financially sustainable for all parties involved.

This RNG facility uses the Sulfurex®BR & Carborex®MS.

For key biogas contaminants, DMT offers one or a combination of technologies. The technology selection is based on an analysis of your biogas composition, inlet gas flow, pollution load and RNG application. Based on your CAPEX, OPEX and/or TCO needs, we provide our customers with an innovative, economical solution.